You are here

Back to topHow to Choose Converter for Industrial IOT Application

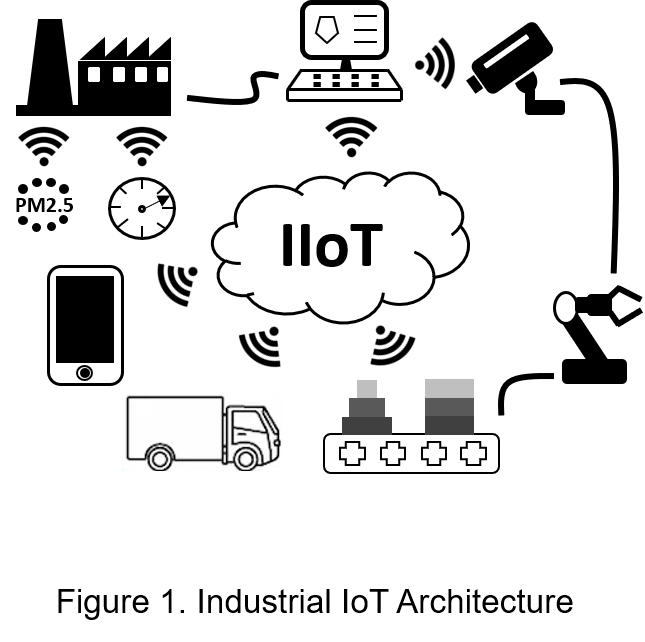

In response to the advent of the era of big data, more and more factories use intelligent devices to monitor and analyze all data in new ways, which achieves the purpose of smart factory. There are many types of intelligent devices, so how to evaluate suitable power converters for Industrial IoT is very important.

This article mentions how to select power converter for battery-powered intelligent devices and provides a formula for calculating the relationship between operating current and battery life, allowing users to understand how often it takes to renew battery to maintain stable system performance.

1. Introduction

The industry in global has entered an era of Industrial Internet of Things (Industrial IoT or IIoT). In smart factories, various devices on the production-line are connected through internetworking, and the ability to analyze large amounts of data, automation, and high interconnection, which can help to improve productive efficiency. The Industrial Internet of Things covers multiple application fields, including industrial machines, medical equipment, transportation, artificial intelligence, and entertainment.

Due to the setting environment or limitation of space, most smart devices cannot be self-powered, so the devices rely on external batteries to maintain normal operation. The common solution is to use lithium batteries or nickel-cadmium batteries for power supply, but the limited size of smart devices is not suitable for built-in multiple batteries, so that smart devices need to replace batteries frequently.

2. Select the Converter for Battery-Power

Battery-powered converters require low power consumption and small package size. The design goal is how to extend the battery life and prevent users to renew battery in a short period of time. Therefore, whether the converter states in normal mode or standby mode, low consumed current can result to reduce power consumption and increase lifetime.

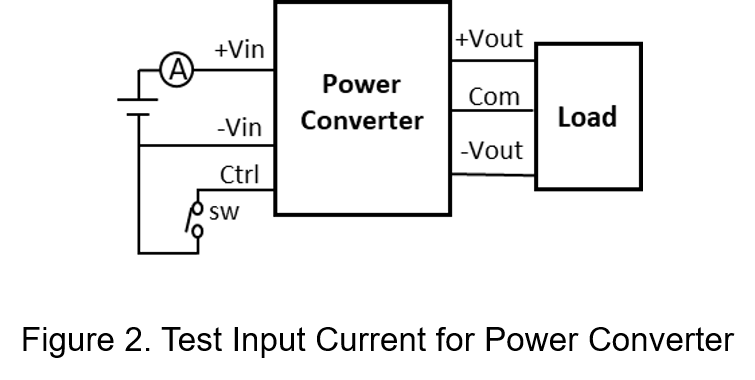

When converter doesn’t connect to load, use a multimeter in series with the battery to measure the input current through opening or shorting the control pin to obtain the quiescent current and standby current. The user can switch the working mode according to different applications. In other words, the smart device is not woken up because the converter switches to the standby mode through the Ctrl pin shorting to GND. The operating current in standby mode is mostly tens of nanoamps, which is much smaller than quiescent current, which can reduce the system current. As shown in Figure 2, where sw is a switch for switching control pins.

There are many kinds of battery-powered smart devices, each with different characteristics and applicative limitations, but the same point is that operation time is very short, so most of the time is in standby mode in order to minimize power consumption.

On the other hand, the demand for miniaturized devices in the Industrial Internet of Things is increasing. Therefore, the volume of devices is as light as possible, but at the same time, converter with multiple functions are required to be placed in small packages. These will become design-challenges in future.

In terms of these requirements, the current common solution is to use a non-isolated power converter, which is implemented in SMD package. Non-isolated power converter combines high conversion efficiency, low standby current and wide input voltage range, and those features are suitable for portable smart device applications where a single power supply is independent.

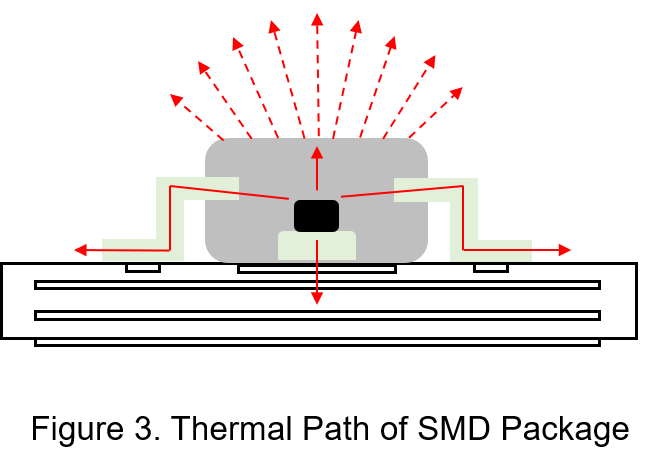

The heat dissipation effect of the SMD package is an important issue. The length of the copper foil trace on the printed circuit board needs to be shortened during the design. If the longer the trace, the higher the line impedance and the larger the standby current. Therefore, shortening the high current copper foil trace which can effectively reduce the excess heat energy generated during converter operating. If the heat energy cannot be dissipated through conduction, convection and radiation, excessive heat energy will accumulate inside the power converter module.

Hence, high conversion efficiency converter for SMD package must be used and cannot operate under heavy load for a long time, otherwise the internal heat-energy is dissipated diffcultly, and then causes the case temperature to increase out of control.

The radiation heat dissipation path of the SMD package is mainly from the converter surface to the atmosphere, as shown by the dotted arrow in Figure 3, and the conduction heat dissipation from the converter pin to the copper foil of the printed circuit board, as shown in the solid arrow in Figure 3.

The heat energy dissipation inside converters is slowly, and the surface of the SMD package is also very small, so the heat dissipation effect of radiation from the surface of the converter is limited. In contrast, the heat source inside the converter mostly conducts heat energy from each pin to the printed circuit board effectively. In view of the above, power converters use surface-array-attach technology to enhance conduction and heat dissipation to the external environment, which is often used in space-constrained applications such as battery-powered IIoT devices.

3. How to Estimate Battery Life

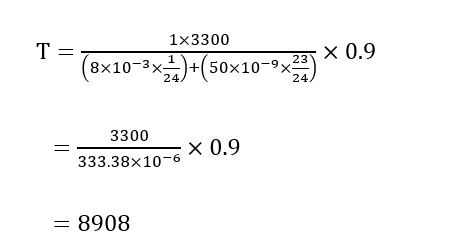

Users often ask how often should I replace new battery? how long is battery life? And always worry that the new battery will not last, or the trouble of replacing the battery too often. Therefore, evaluating battery life in advance can know how often to renew battery. The battery life is estimated by the battery capacity and the average current consumed by the load. The formula is as follows:

T is the service life of the battery, in hours; N is the number of batteries; C is the battery capacity, in milliamp hours; A is the average current consumption, in milliamps; L is the natural consumption rate of about 0.9.

The first step is to choose a common type of battery. In daily life, there are quite electronic products that choose 18650 lithium battery as a power source, which is widely used smart home and electric vehicles. The nominal voltage of a single 18650 lithium battery is 3.7V, and the common capacity is 1200~3300mAh.

Each intelligent devices needs to indicate the current consumption in normal operation, sleep, and standby modes, respectively. Users should keep these values in mind as an evaluative standard for battery life. The second step is to estimate the current of the intelligent devices. It roughly divides the total current consumption into operating current (Io) plus standby current (Is), as follows:

For example, using a lithium battery 186502 with standard voltage of 3.7V and battery capacity of 3300mAh, it only works normally for one hour a day, and the operating current of the converter is 8mA; the rest of the time is in standby mode in one day, and the standby current of the converter is 50nA, the longest battery life is calculated as follows:

According to the results of the above formula, the battery can be used for about 8908 hours, that is, the product can maintain estimate operation for about one year without replacing the battery. The actual battery life will be shorter than the calculated value by (1) because non-ideal factors are affected, so the user needs to estimate the battery life

However, there are still many non-ideal factors that reduce battery life, one of which is temperature. Extreme temperatures will affect the battery capacity. For example, low temperature environment makes the capacity of lithium battery attenuate rapidly; high temperature environment will accelerate the deterioration of the chemical materials inside the battery and the potential risk of battery swelling. So, ambient temperature does affect the battery life, and it is necessary to control the temperature in anytime to increase performance.

4. Conclusion

In battery applications, total system power consumption is extremely important for consumer electronics. This article mentions the preference for low-current and small package size power converters to meet the IIoT applications, and then the battery life formula is used to calculate how much the current of converter should be designed to operate in the desired lifespan.

CTC is service provider for high-end power modules (DC to DC Converter and AC to DC Converter) for critical applications worldwide since 1987. We aim to be business generator and a virtual business unit. CTC is your own team with 35 years of experience for a strong business program from market research, product definition & development, supply chain management and total technical services.

CTC is the only corporation certificated with ISO-9001, IATF-16949, ISO/TS22613 (only company in Taiwan with Silver Performance Level) and ESD/ANSI-2020. We are specialized for critical and higher-end applications, such as Industrial, Railway, E-mobility, Medical etc. Our technical competences are ultra-wide input voltage up to 12:1, wide Operating temperature from -40°C to 110°C, high insulation level up to reinforced and 2MOPP, high isolation level up to 20KV DC/ min, specific EMC solutions with EMI Class A Built in. Besides, CTC began implementing Smart Manufacturing to achieve dynamic deliveries with globalized production sites.

CTC powering your core !