You are here

Back to topUnderstanding the Differences Between HBM and IEC 61000-4-2 ESD Standards

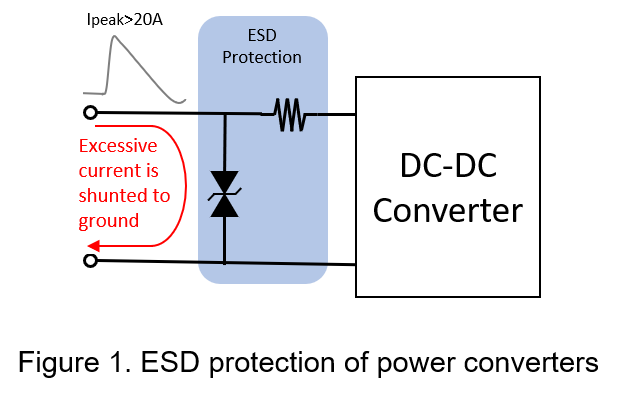

Power converters operating in harsh environments are frequently exposed to high-voltage transients at input or output nodes. To ensure product reliability, adherence to device-level HBM and system-level IEC 61000-4-2 standards for ESD protection is essential. Unfortunately, these ESD standards are often misunderstood, leading to failures even after verification. For users, it is crucial to understand all testing standards, and this article aims to describe two common ESD models, standard testing methods, and discharge differences.

Introduction

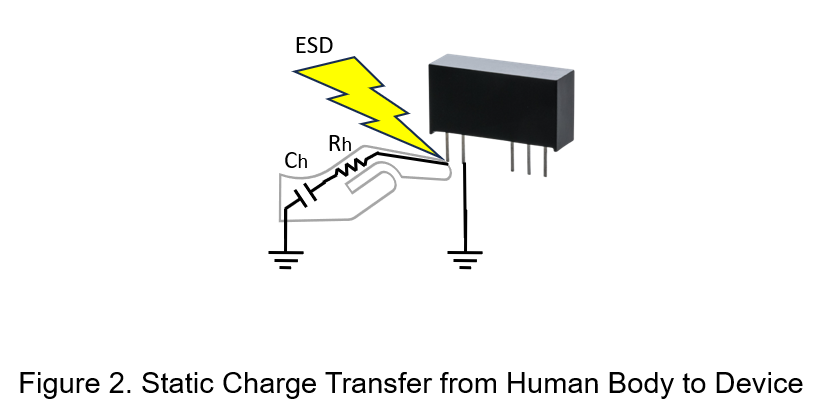

Industry 4.0 systems, consisting of sensors, embedded PLCs, and storage devices, are mostly placed outdoors, making protection from external transient interference, such as electrostatic discharge (ESD), critical. ESD occurs when a charged object comes near or contacts another object, resulting in a redistribution of charge, potentially causing a high current to flow in a short time, leading to hazardous conditions.

ESD frequently occurs in daily life, such as when static charges accumulate on equipment during vibration on trays or movement on conveyors. Once the pins of a power converter make contact, the static charge transfers, generating a transient high voltage that can damage internal components. The human body is also considered a charged conductor that can transfer static to any device.

During the design and production phases, it is essential to consider ESD risks and implement protective measures to shield against transient damage.

Introduction to Electrostatic Discharge Testing Standards

To properly assess the robustness of a system’s resistance to ESD, many testing standards have been developed. They simulate the discharge from charged objects or humans to ground via the power converter. Presently, power converters undergo strict ESD tests before leaving the factory, enabling their use in broader fields. This means that even in cold, dry regions prone to static electricity, electronic products will not have their lifespans affected.

(1) Human Body Model (HBM)

The HBM is the most widely accepted ESD test. When walking on a floor, static charges accumulate in the body. Once a finger touches or nears the pins of a power converter, the static charge is released to the ground through the power converter, producing several amperes of current in a very short time, which can cause irreversible damage.

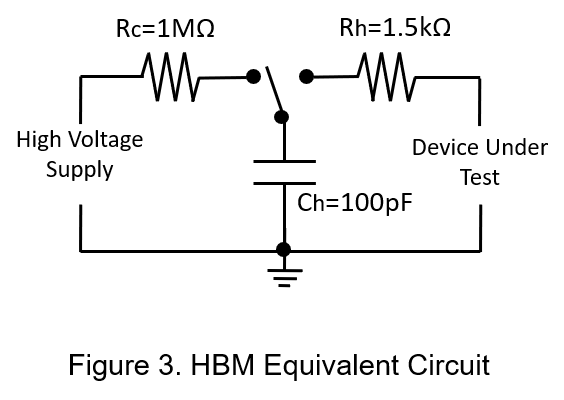

The HBM simulates the human body's discharge circuit, as shown in Figure 3. The charged human body is modeled by 100pF. A transient voltage passes through a 1MΩ resistor to charge the 100pF capacitor. When the charged body touches or nears metal pins, it discharges to the ground or a lower potential through a switch and 1.5kΩ resistor.

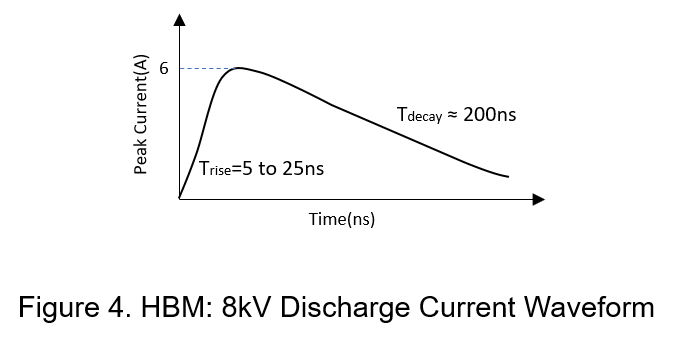

Typically, the rise time of discharge current in HBM testing is around 5 to 25ns, and the discharge decay time is approximately 200ns.

(2) IEC 61000-4-2

IEC 61000-4-2 is a system-level standard that outlines electromagnetic immunity requirements for electronic equipment. The goal of this international test is to ensure that users can withstand transient events under various operating conditions. Therefore, all power converters must undergo testing under transient conditions that simulate real-world situations without damaging the appearance or internal components.

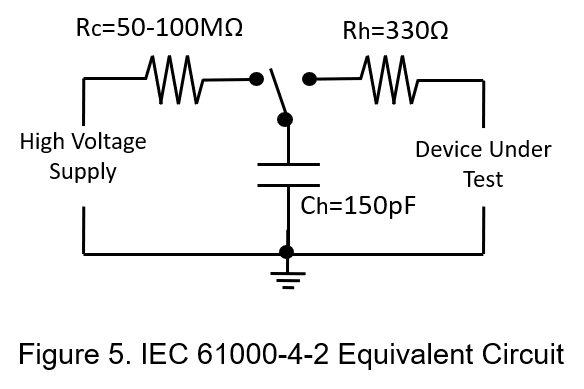

Unlike HBM, the IEC 61000-4-2 standard uses a 150pF charge to store static. When an ESD gun generates a high-intensity electrostatic field, it induces a discharge onto the power converter. At that point, a 330Ω resistor discharges the static to the pins of the power converter.

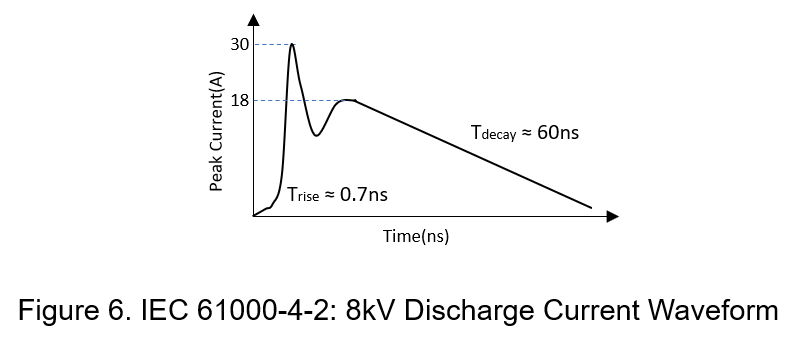

The ESD discharge waveform is shown in Figure 6. Due to the discharge resistance being only 330Ω, the discharge rise time is less than 1ns, and most of the transient energy is dissipated within the first 60ns. Therefore, the system and ESD tests exhibit higher energy current waveforms compared to HBM tests.

IEC 61000-4-2 defines two test methods: contact discharge and air discharge. Contact discharge involves directly touching the test object, such as a power converter, with the ESD gun. If the space between components is too small to make direct contact, air discharge should be used, where the ESD gun is brought close to the pin until an arc occurs.

|

Contact Discharge |

Air Discharge |

||

| Level | Test Voltage (kV) | Level | Test Voltage (kV) |

| 1 | 1 | 1 | 2 |

| 2 | 2 | 2 | 4 |

| 3 | 6 | 3 | 8 |

| 4 | 8 | 4 | 12 |

| XNote1 | Special | XNote1 | Special |

It is worth noting that both test methods are considered equivalent at each level, for example, a level 3 contact discharge of 6KV is equivalent to an air discharge of 8kV.

(3) Differences between HBM and IEC 61000-4-2

From Figures 3 and 5, it can be seen that the charging capacitor and discharge impedance for HBM and IEC 61000-4-2 are 100pF/1.5kΩ and 150pF/330Ω, respectively. This indicates that the IEC 61000-4-2 standard has a larger charging capacitor and lower discharge resistance. Based on these characteristics, the discharge current of IEC 61000-4-2 is significantly higher than HBM, with the second peak discharge current reaching about 18 amperes, far exceeding the maximum discharge current of HBM.

This means that even if a power converter passes an 8kV component-level HBM test, it may still be damaged by the 8kV system-level IEC 61000-4-2 test.

|

Applied Voltage(kV) |

HBM Peak Current(A) |

IEC 61000-4-2 Peak Current(A) |

| 2 | 1.33 | 7.5 |

| 4 | 2.67 | 15 |

| 6 | 4.00 | 22.5 |

| 8 | 5.33 | 30.0 |

| 10 | 6.67 | 37.5 |

This current difference is critical for whether the power converter retains its original characteristics. Therefore, designers adopt stricter standards to ensure that the product can withstand real-world conditions.

Additionally, Figures 4 and 6 show that at the same test voltage, the rise time of the discharge current for the two tests is different. The rise time of the HBM discharge current is around 25ns, while for IEC 61000-4-2, the rise time is less than 1ns. This pulse current dissipates most of its energy in a very short time, meaning that a power converter compliant with HBM may not pass the transient current energy of IEC 61000-4-2.

Another difference is the number of ESD pulse currents applied during a single test. The HBM standard limits it to one positive pulse and one negative pulse, while IEC 61000-4-2 requires at least ten positive pulses and ten negative pulses. The electrical characteristics of the power converter are then observed to determine if it meets the standard.

In practice, power converters are subjected to multiple ESD shocks during operation, so converters that comply with IEC 61000-4-2 have a higher tolerance to ESD shocks.

Conclusion

Power converters must comply with international ESD standards to enhance reliability. In general, IEC 61000-4-2 involves larger discharge currents, shorter transient discharge times, and more frequent current pulses. Overall, IEC 61000-4-2 requires electronic products to withstand significantly more energy than HBM. End users should understand the ESD specifications in product datasheets and choose faster and more robust protective components to shield power converters from ESD shocks.

CTC is service provider for high-end power modules (DC to DC Converter and AC to DC Converter) for critical applications worldwide since 1987. We aim to be business generator and a virtual business unit. CTC is your own team with 35 years of experience for a strong business program from market research, product definition & development, supply chain management and total technical services.

CTC is the only corporation certificated with ISO-9001, IATF-16949, ISO22613(IRIS, AFNOR silver certificate), and ESD/ANSI-2020. We can 100% ensure not only the product, but also our workflow and service to match quality management system for every high-end application from the very beginning. From design to manufacturing and technical support, every single detail is operated under highest standard.