You are here

Back to topOver Load Protection

Most switch-mode power converters during overload conditions employ various schemes to not only protect themselves, but also protect the system from further damage by limiting load during fault conditions. The detailed description in this article allows users to understand the information required for overload current protection, and to avoid the continuous occurrence of excessive load current problems by measuring the current limiting method in hiccup mode.

Introduction

The output voltage of the switching power converter must meet the load requirements. When the output load power is higher than the specification range or under improper operation, the output voltage may be in unstable state at the design level. The power converter overheats due to overloads for a long time, which is not only difficult to select heat fins, but also reduces product reliability. In special cases, it may even damage the user’s printed circuit traces, causing fires and other serious dangers. Therefore, always check the power supply’s instruction manual to be sure you understand the precautions associated with the power product’s overload protection feature.

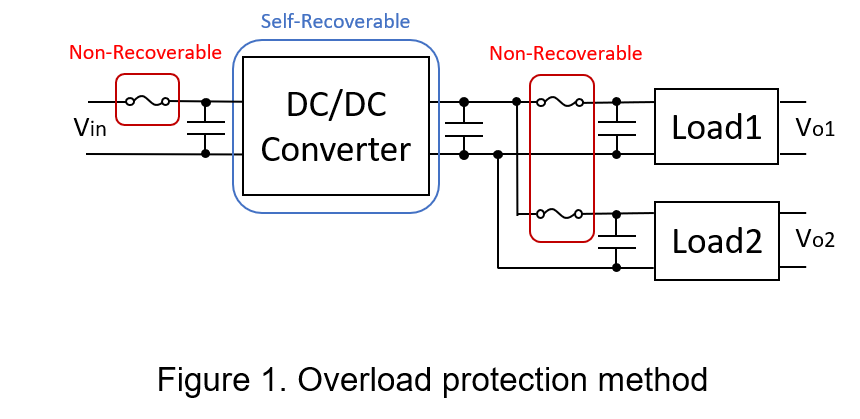

There are many ways to protect the overload condition of power converters, and the choice of protection scheme depends on cost, complexity, applicable safety standards, etc. Overload protection methods are broadly classified into non-recoverable types and recoverable types. The non-recoverable type is most commonly protected by using a fuse or a circuit breaker, which is usually placed in series with the protected circuit on the main load path because its negligible impedance in the overall circuit. After overload occurs, the fuse meeting the load requirements must be replaced immediately, and it must be noted that the fuse rating must not be increased arbitrarily; the recoverable type is designed from within the power converter and is not determined by external components. The following sections discuss recoverable types of protection.

Overload Protection Method

Once overloading condition occurs, the fuse is blown out or the circuit breaker is tripped, which means the main current path is disconnected, and then personnel need to install a new fuse or reset the circuit breaker. This is really not in line with the trend of industrial automation.

Most power converters have a built-in overload protection. This protecting function shut down the output voltage until the output load drops below specification value in overload item. If load recovery normal, power converter automatically restarts. There are many methods to implement overload protection (OLP). Common methods include: constant current mode, foldback current mode, hiccup mode and other current limiting methods.

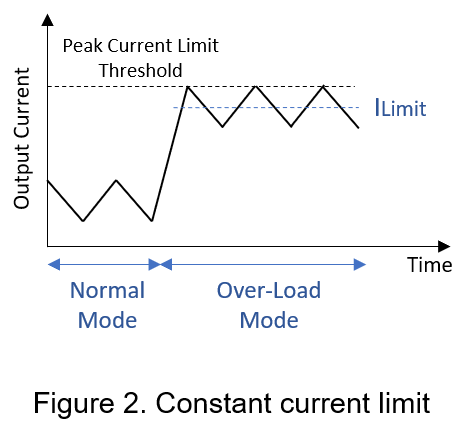

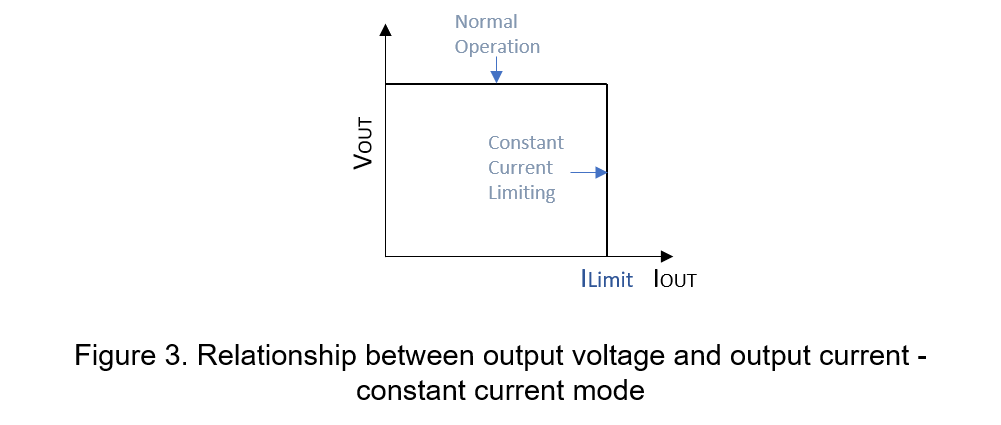

- Constant Current Mode

Overview of this method is to detect peak inductor current flowing through the power transistors, and then limit the duty cycle ratio of power transistors, which can achieve current limitation in each cycle. In normal operation, the inductor is charged through power switch, and the power transistor is turned off, at the same time, discharged to the load end. When overload condition happens, the output current will remain at the limit value(ILimit) and the output voltage will slowly decrease to zero.

Figure 2 shows the output current waveform of power converter in normal mode and overload mode. Once the inductor peak current exceeds the peak threshold, the output current will remain constant in ILimit, while output voltage will gradually decrease. At this time, the power consumption of the power components is relatively large, and the more power loss is converted into heat energy, causing the temperature of the housing to rise and conversion efficiency to be low

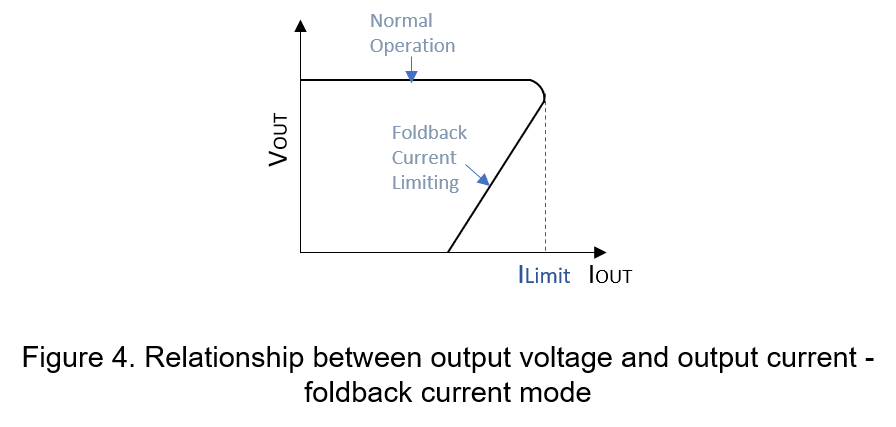

- Foldback Current Mode

This method is similar to the constant current mode. The main difference is that when the inductor current initially exceeded threshold, the output voltage also drops to zero, but output current returns to less than the normal, not zero. As shown in Figure 4, when inductor current rise to threshold value, output voltage gradually decreases by changing the duty cycle ratio, so that output current can be used to fold back the current to a lower level. However, the disadvantage of foldback current method is that it cannot completely self-recovery. Because power converter may work in the foldback area when overloading, the converter needs to be restarted or the power supply cut off and then can be able to return normal operation.

It can be seen that the low output current will reduce the power consumption of the power converter during the current limiting period in order to prevent the power transistor temperature from being unstable or thermal runaway, which keeps power converter in its Safe Operating Area (S.O.A.).

- Hiccup Mode

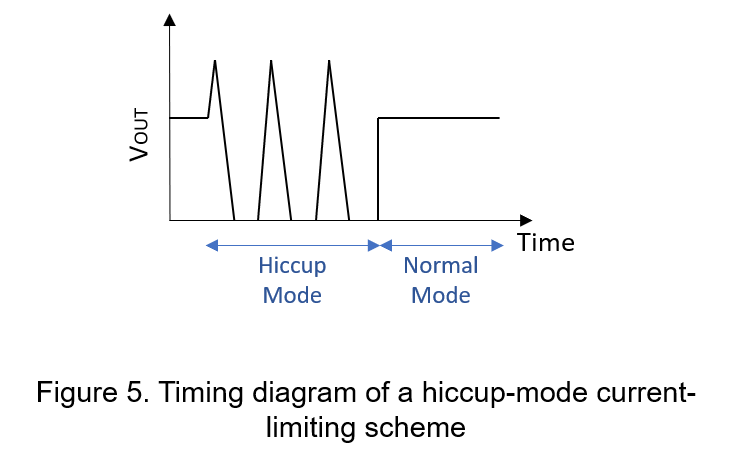

This method is that the converter output load exceeds the rated power, and the power converter will reduce or cut off the output power, which represents the overload protection enabled. When the protection circuit detects the output overload, meaning start in hiccup mode, the output voltage and output current immediately drop to zero. Then, the converter will try to restarted in a short time. Assuming overload has not been eliminated, the output voltage and current will drop to zero immediately again. Until the overload condition is eliminated, converter will back to normal, as shown in figure 5.

This method overcomes the shortcomings of those protection discussed above. First, the hiccup solution reduces the average load current by the power converter turns on and off intermittently, which speeds up the converter cooling and then solves the overheating problem; Second, once overload condition is eliminated, the power converter automatically restart normal operation immediately.

Experiment

Choose a power converter with overload protection function. The following table lists the DC-DC power converter specifications in experiment.

| Package | 1x1” |

| Input voltage | 9~36V, Nom. 24V |

| Output voltage | 12V |

| Output current(max.) | 2500mA |

| Overload protection(typ.) | 170% |

| Efficiency (typ.) | 90% |

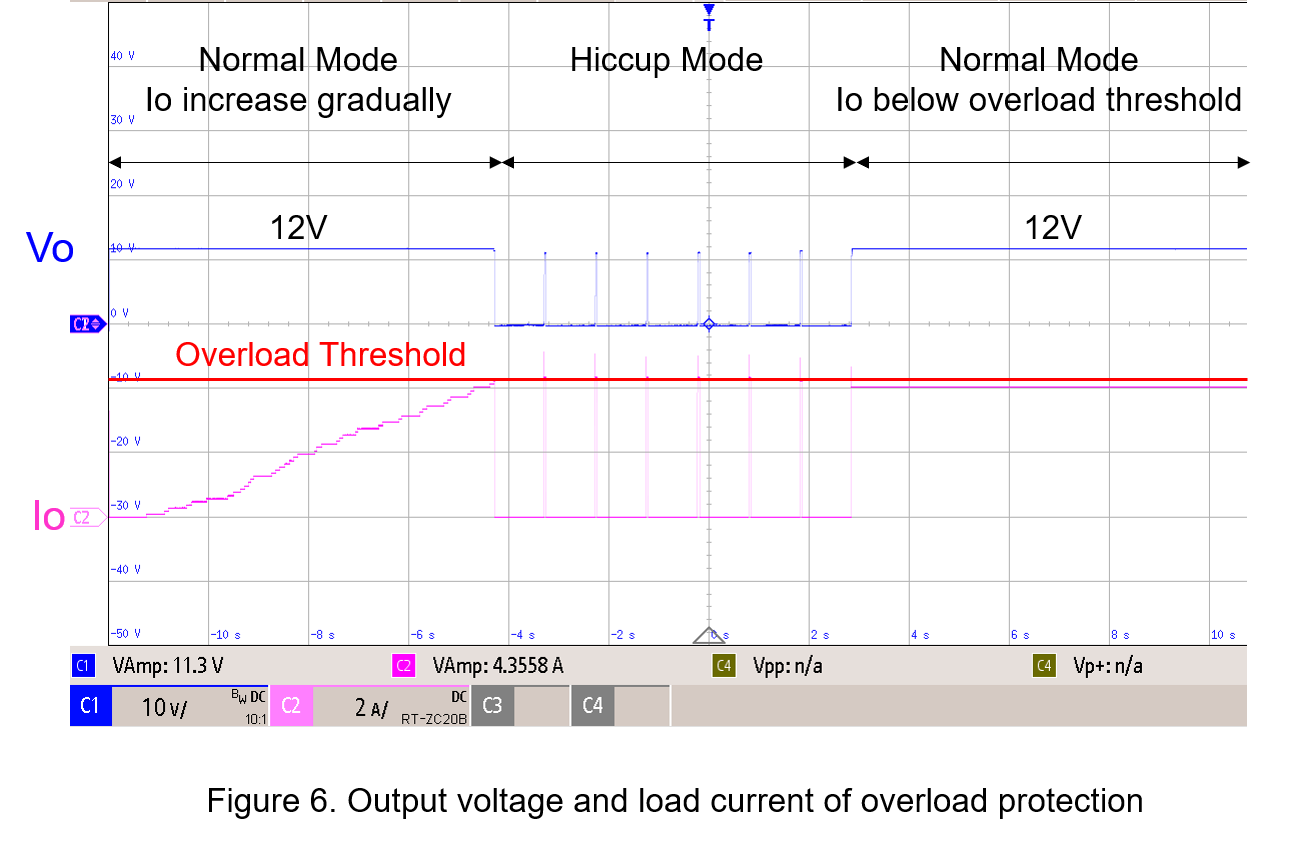

The power supply is used as the input power source, the output terminal of the power converter is connected to the electronic load machine and digital ammeter, and use the oscilloscope to observe the output voltage and load current waveform. During the experiment, the input voltage of power converter remains unchanged, and then output current (Io) was gradually increased until 170% of maximum load current, i.e. overload threshold of 4.25A. At this time, the power converter began to enter hiccup mode, and then both the output voltage and load current occurs during turn-on and turn-off intermittently in order to reduce the average current. When the load current is slightly lower than 4.25A, the power converter automatically restarts normally.

Conclusion

Overload protection enhances the reliability of power converter, includes to prevents electronic device output pins shorting, ground faults, and incorrect loads switching. Therefore, overload protections have turned into basic function. Among them, hiccup current limiting protection not only solves heat-dissipation problem but also self-recovery startup, so hiccup mode is a most accepted way.

CTC is service provider for high-end power modules (DC to DC Converter and AC to DC Converter) for critical applications worldwide since 1987. We aim to be business generator and a virtual business unit. CTC is your own team with 35 years of experience for a strong business program from market research, product definition & development, supply chain management and total technical services.

CTC is the only corporation certificated with ISO-9001, IATF-16949, ISO22613(IRIS, AFNOR silver certificate), and ESD/ANSI-2020. We can 100% ensure not only the product, but also our workflow and service to match quality management system for every high-end application from the very beginning. From design to manufacturing and technical support, every single detail is operated under highest standard.